Schuster Powers Up Capital Electric with Efficient Tilt-Up Construction

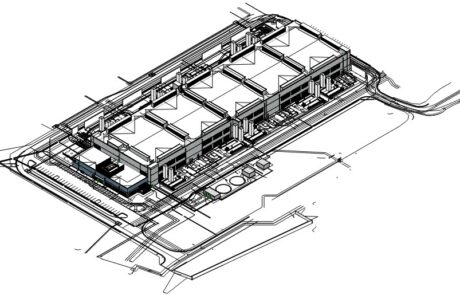

Schuster Concrete Construction is proud to have played a key role in the development of Capital Electric’s impressive 362,880 square foot tilt-up warehouse project. This collaboration exemplifies Schuster’s commitment to providing innovative and efficient solutions for industrial construction needs.

Speed, Savings, and Strength: The Advantages of Tilt-Up

The Capital Electric project utilized the tilt-up construction method, a technique lauded for its speed, cost-effectiveness, and exceptional durability. This method involves crafting large concrete panels on-site, then strategically positioning them using cranes. This streamlined approach minimizes disruption to the surrounding area and allows for swift project completion – a significant advantage for businesses eager to get operational quickly.

Schuster: A One-Stop Shop for Success

The success of the Capital Electric project hinged on the seamless collaboration between Schuster Construction and Schuster Ready Mix. This unique synergy ensured complete control over the concrete lifecycle, from meticulous on-site manufacturing by Schuster Ready Mix to the flawless installation delivered by Schuster Construction. This integrated approach guaranteed consistent quality and efficient workflows throughout the project.

Building a Lasting Legacy

The Capital Electric warehouse stands as a testament to Schuster’s dedication to excellence in concrete construction. The project not only showcases the speed and cost-efficiency of tilt-up construction, but also highlights Schuster’s ability to deliver exceptional results through in-house expertise and collaboration.

Project Highlights

- 10 Month Project

- 17,000 Cubic Yards of Concrete Used

- 5-10 Million Dollar Contract Value

Project Details

CLIENT

Glen Arm Building Company